A better function of aluminum substrate is to generate ceramic printed circuit directly on the aluminum plate. First, a layer of 100 μ m thick aluminum oxide film is grown on the surface of aluminum by micro arc oxidation, then the circuit layer is made by sputtering screen printing. The advantage of using this gate is strong binding force, the thermal conductivity is as high as 2.1w/m.k, the thermal expansion coefficient of the oxide layer is similar to that of aluminum, Therefore, its peel strength is more than 5N / mm. It is only because the manufacturing process of the ceramic aluminum substrate is complex the cost is high, so it is rarely used.

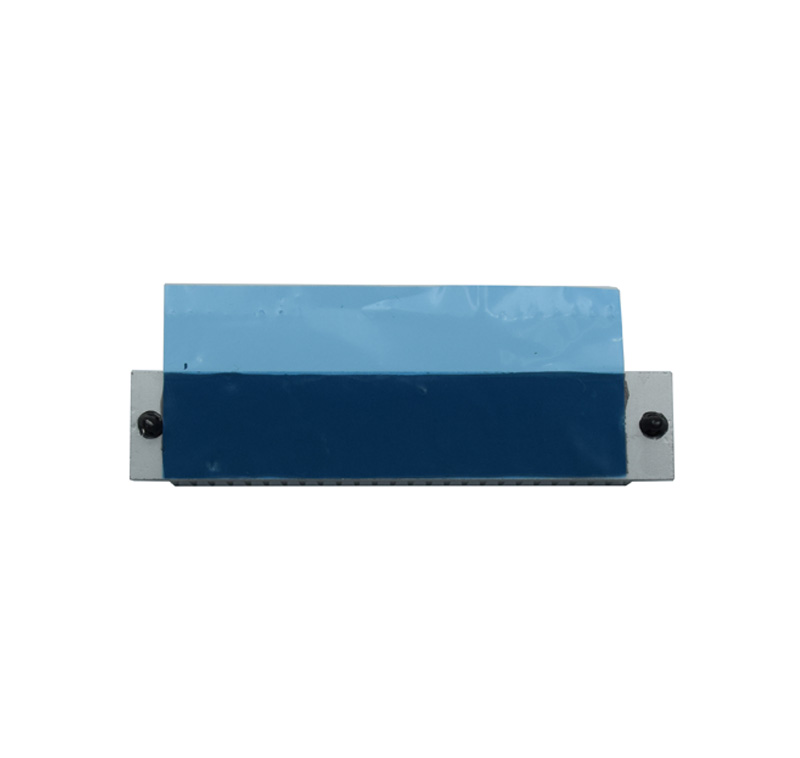

Although the aluminum substrate is only a special printed board, it bears a very heavy task of heat dissipation, only the heat conduction of the insulating layer is good the bonding is firm, but also its shape must match the shape of the radiator. For example, in the street lamp, it is usually a rectangular shape, in the spotlight, it is usually round, in the fluorescent lamp, it is usually a long strip. In order to obtain better thermal conductivity, copper substrate with better thermal conductivity is sometimes used.

Today, almost most LED lamps use aluminum substrate. In order to conduct electricity heat conduction, the copper foil of the circuit on the aluminum substrate should have enough thickness width, with the thickness between 35um 280um. The width should cover all the substrates as much as possible, so as to transmit the heat. The next layer of insulator requires good insulation heat conduction.

However, these two functions are different. Generally, the conductor has good heat conduction function, while the insulator has poor heat conduction function. It is difficult to achieve good heat conduction insulation, it is also a scientific research topic. Today, a kind of modified epoxy resin epoxy glass cloth adhesive with ceramic filler is used. The copper foil insulator is bonded to the aluminum plate by hot pressing. There are some LED lamps, although the radiator is carefully designed, but it will soon break down. The problem is that the aluminum substrate with large thermal resistance the aluminum substrate with poor peel strength is used. In a period of time, the circuit film will be warped up, which will conduct heat at all, the LED will soon burn out.

Telephone:13423468768 13620030210

Mail box:willson.xu@huiqitech.com

Address: Room 605, building 1,5 Ching Wai Wu Road, Tung Hang Town, Dongguan